Nvidia Robotics is revolutionizing the landscape of industrial automation with its cutting-edge digital twin technology. By enabling manufacturers to create real-time, 3D virtual replicas of their factories, Nvidia is paving the way for more efficient, AI-driven autonomous factories. These innovations allow for the integration of AI robotics, which can analyze and optimize manufacturing processes to reduce waste and improve productivity. As industry leaders adopt Nvidia Omniverse for detailed simulations and predictive modeling, the future of robotic automation appears not only promising but transformative. With each advancement, Nvidia Robotics emphasizes its commitment to enhancing both the efficiency of operations and the synergy between human workers and intelligent machines.

The emergence of Nvidia Robotics marks a significant turning point in the realm of automation and smart manufacturing. This advanced technology leverages sophisticated simulation software and generative AI to reshape how factories operate. By utilizing virtual modeling tools, companies can create digital twins of their facilities that support AI-driven innovations and enhance performance metrics. As businesses seek to harness the power of autonomous systems, the Nvidia platform stands as a crucial player in facilitating robotic advancements that promise to streamline operations. In this new era of industrial automation, the integration of AI and robotics presents a unique opportunity for companies to redefine their production capabilities.

The Rise of Nvidia Robotics in Industry 4.0

Nvidia is at the forefront of revolutionizing the manufacturing sector with its advanced robotics solutions, pushing the boundaries of Industry 4.0. By integrating digital twin technology with AI robotics, Nvidia is enabling manufacturers to create virtual representations of their factories. This innovative approach allows businesses to analyze their processes in real-time, driving efficiency and reducing costs. The company’s emphasis on AI-driven solutions promises a future where robotic automation is seamlessly integrated into the manufacturing landscape, ultimately transforming how products are designed and produced.

Moreover, the collaboration with global manufacturers such as BYD Electronics and Siemens highlights Nvidia’s influence on a worldwide scale. These partnerships aim to harness the power of Nvidia’s robotics stack and any technology needed to aid in the transition to autonomously operated factories. As robots become increasingly capable of performing complex tasks, the vision of fully autonomous production lines becomes more achievable, paving the way for a smarter and more efficient manufacturing environment.

Exploring the Nvidia Omniverse for Enhanced Simulation

The Nvidia Omniverse is a state-of-the-art platform designed to simulate real-world scenarios for robotics applications. By creating a digital twin of physical factories, the Omniverse allows engineers to conduct tests and refine their automation processes without the risk and cost associated with real-world trials. This platform is pivotal for training robots, providing an interactive environment where AI systems can learn and adapt to different scenarios, ensuring that they are well-prepared for real-life operations.

Such simulations are not just beneficial for development but also play a crucial role in optimizing factory layouts and operations. With tools like the Isaac Manipulator, manufacturers can visualize and strategically place robotic arms and sensors to enhance productivity. As Madisson Huang, Nvidia’s director of product marketing, points out, using the Omniverse for simulation and planning can lead to significant advancements in industrial efficiency, thus setting the groundwork for smarter manufacturing solutions.

The Impact of Autonomous Factories on the Manufacturing Sector

As manufacturers increasingly adopt autonomous systems, Nvidia’s platform showcases the crucial role digital twin technology plays in this transformation. Autonomous factories leverage high-performance robotics to streamline operations, minimize human error, and respond dynamically to production demands. By utilizing AI models and real-time data analysis, these factories can operate efficiently, reducing downtime and maximizing output.

Furthermore, the introduction of robotic assistants in manufacturing workflows not only increases productivity but also enhances workplace safety. As robots take over repetitive or hazardous tasks, human workers can focus on higher-level responsibilities that require creativity and problem-solving skills. This shift towards automation, supported by Nvidia’s robotics solutions, presents a new vision for the future of work within the manufacturing sector, where human-robot collaboration becomes the norm.

Nvidia Robotics: A Game Changer for Warehouse Automation

In the realm of warehouse operations, Nvidia Robotics is setting new standards with its integration of AI and robotic automation. The use of digital twin technology enables warehouse managers to simulate logistics processes and optimize inventory management, making it easier to track goods in real time. By analyzing inefficiencies within existing layouts, companies can implement changes that drastically enhance productivity and reduce operational costs.

Moreover, Nvidia’s advances such as the Isaac Perceptor offer innovative solutions for automating manual tasks, allowing robots to assist human workers rather than replace them. This complements the workforce by providing support in repetitive tasks, thus contributing to a safer and more efficient environment. As Nvidia continues to innovate in this space, the potential for transforming warehouse logistics with cutting-edge technology is immense.

Harnessing the Power of AI Robotics in Digital Twins

The convergence of AI robotics with digital twin technology represents a significant advancement in manufacturing and logistics. Nvidia is pioneering this integration, allowing industries to create virtual models of their production systems. These digital twins serve as an essential tool for testing and iterating improvements in robotic systems, enabling manufacturers to identify and resolve inefficiencies before they can impact physical operations.

Through the use of generative physical AI, Nvidia’s robotics stack enables real-time data processing, which allows for sophisticated simulations and decision-making processes. As companies adopt these technologies, the landscape of manufacturing and logistics is poised for unprecedented transformation, leading to cleaner, more efficient, and fully automated operations.

Foxconn’s Adoption of Nvidia’s Omniverse for Digital Twins

Foxconn, a leading electronics manufacturer, is leveraging Nvidia’s Omniverse platform to propel its efforts in building digital twins of its manufacturing facilities. This strategic move is set to revolutionize how Foxconn approaches its production lines, providing a robust framework for simulating various operational scenarios. The ability to test and refine processes in a virtual environment allows Foxconn to optimize workflow and enhance overall efficiency, ultimately leading to substantial cost savings.

The deployment of digital twins will also aid in training robotic systems to perform intricate tasks within the manufacturing process. As Young Liu, Foxconn’s chairman, emphasizes, this innovation will enable a shift toward greater automation, aligning with the company’s goal of redefining industrial efficiency. Through utilizing Nvidia’s Omniverse technology, Foxconn is well-positioned to lead the charge in manufacturing automation and digital transformation.

Realizing the Benefits of NVIDIA’s Robotic Automation Technologies

Nvidia’s robotic automation technologies offer manufacturers a significant edge in a highly competitive landscape. By incorporating AI robotics into their workflows, companies become capable of achieving unprecedented levels of accuracy, speed, and productivity. The Isaac Robotics Platform, notably, empowers manufacturers to develop and deploy capable robotic systems that enhance operation while ensuring safety and efficiency within various production environments.

Additionally, the suite of software products available from Nvidia not only facilitates the creation of digital twins but also enhances the overall ecosystem of robotic automation. This integration of AI, machine learning, and robotics is spearheading advancements in automation, signaling a transformative shift toward autonomous manufacturing processes that promise to redefine industrial standards and expectations.

Transformative Innovations in Robotic Automation by Nvidia

Nvidia’s commitment to developing transformative innovations in robotic automation is evident through its proprietary technologies. By introducing cutting-edge products that enhancing AI capabilities within robotics, Nvidia is enabling manufacturers to automate previously complex tasks. The implementation of AI and machine learning in robotic systems results in increased precision, reduced operational costs, and improved safety for human workers.

Moreover, the futuristic aspect of Nvidia Robotics not only focuses on automation but also on creating collaborative environments where robots work alongside humans. This fusion of human intelligence with robotic efficiency translates into higher productivity and smarter workflows, allowing industries to meet growing demands for rapid production while maintaining quality and consistency.

The Future of Robotics with Nvidia’s AI Innovations

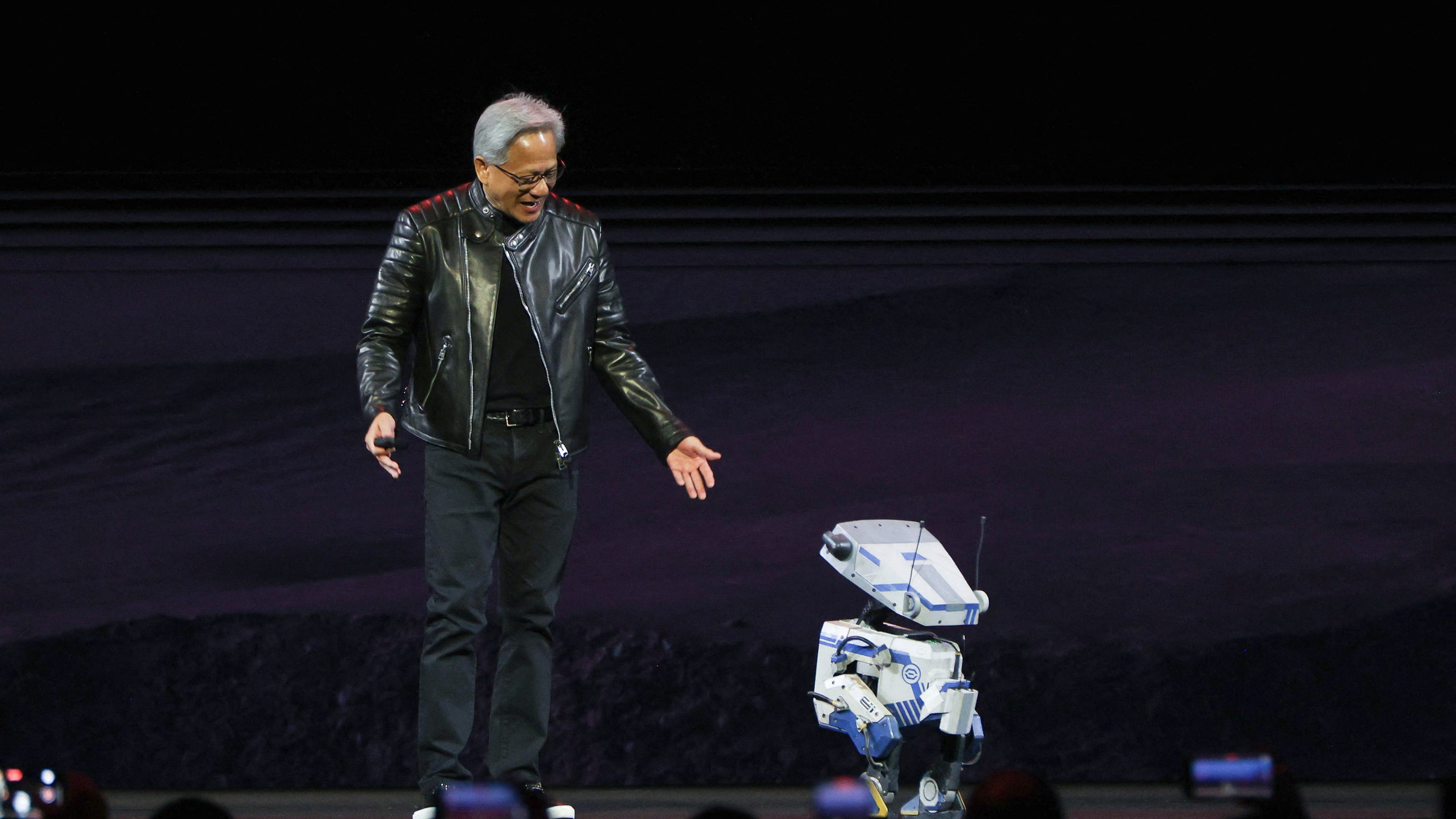

With the rapid advancement of AI technologies, Nvidia is positioned to shape the future of robotics significantly. As Jensen Huang stated, “everything that moves will one day be autonomous,” highlighting the profound impact AI will have on various sectors. Nvidia’s continuous investment in AI robotics and digital twin technology holds the promise of redefining how we conceptualize autonomy and efficiency in manufacturing.

Through a holistic approach that combines advanced simulation capabilities with real-time robotics, Nvidia is working to enhance the operational framework of factories worldwide. This forward-thinking strategy not only focuses on improving production but also aims to create sustainable systems that benefit both the economy and the environment. The journey toward fully autonomous factories is on the horizon, powered by Nvidia’s groundbreaking innovations.

Frequently Asked Questions

What is Nvidia Robotics and how does it utilize digital twin technology?

Nvidia Robotics is an advanced platform that employs digital twin technology to create virtual replicas of physical factories. By using Nvidia’s Omniverse, manufacturers can simulate their operations in a real-time 3D environment, allowing for detailed analysis and optimization of production processes. This technology enables efficient planning, testing, and automation, paving the way for a future of autonomous factories.

How does Nvidia’s Omniverse enhance robotic automation in manufacturing?

Nvidia’s Omniverse greatly enhances robotic automation by providing a collaborative platform where developers can build accurate 3D simulations of factories. It integrates various robotics technologies, including AI robotics and the Isaac platform, to facilitate real-time testing and development of robotic systems. This leads to improved efficiency, safety, and operational capabilities in modern manufacturing environments.

What role does AI robotics play in Nvidia’s robotic solutions?

AI robotics is central to Nvidia’s robotic solutions, particularly through its Isaac AI platform. This technology allows robots to perceive and understand their environment, making autonomous decisions to execute tasks. By integrating AI robotics with digital twin technology, Nvidia enables more intelligent and efficient robotic systems that can operate effectively alongside human workers in factories.

Can you explain how Nvidia’s Isaac Manipulator functions within automation workflows?

The Isaac Manipulator is a part of Nvidia’s robotics suite, designed to interact and perform tasks in a factory setting autonomously. It leverages AI to recognize objects, navigate environments, and carry out complex actions, such as placing heavy components on autonomous mobile robots. This robotic system is instrumental in streamlining workflows and enhancing the overall productivity of automated factories.

What benefits do autonomous factories bring through Nvidia Robotics?

Autonomous factories powered by Nvidia Robotics provide significant benefits, including increased efficiency, reduced costs, and enhanced safety in manufacturing processes. By employing digital twin technology and AI robotics, these factories can accurately simulate operations to identify inefficiencies, enabling real-time adjustments that lead to smarter production and operational improvements.

How are companies like Foxconn utilizing Nvidia Robotics in their manufacturing processes?

Foxconn is utilizing Nvidia Robotics by implementing the Nvidia Omniverse platform to create a digital twin of its factories. This virtual representation allows engineers to design optimal processes and train robots for enhanced automation and efficiency. Through this advanced technology, Foxconn aims to significantly improve operational workflows across its global manufacturing facilities.

| Key Point | Description |

|---|---|

| Nvidia Robotics Platform | A suite of technologies that enable robotics manufacturers to create digital twins of physical factories, enhancing automation and efficiency. |

| Digital Twins | Allows real-time simulation of factories to optimize performance and integrate AI-enabled robots for manufacturing. |

| Key Manufacturers | Includes companies like BYD Electronics, Siemens, Teradyne Robotics, and Intrinsic using Nvidia’s robotics solutions. |

| Isaac Perceptor Technology | Creates digital representations of factory workers for virtual simulation and testing. |

| Omniverse and GR00T | Nvidia’s platforms for accurate simulation applications, enhancing robotic development. |

| Foxconn’s Adoption | Utilizing Nvidia’s Omniverse to build a digital twin aimed at improving automation and industrial efficiency. |

Summary

Nvidia Robotics is revolutionizing the manufacturing landscape with its cutting-edge digital twin platform, enabling robotics manufacturers to simulate physical factories in real-time. By fostering collaboration between AI-enabled robots and efficient manufacturing processes, Nvidia is paving the way for a more automated future. The integration of advanced technologies like Nvidia Isaac and Omniverse signifies a leap forward in productivity and safety within warehouses. As companies like Foxconn embrace these innovations, the potential for enhancing industrial operations continues to grow, making Nvidia Robotics a key player in the industrial digitalization transformation.